Forged Rolls for Cold Rolling Mills

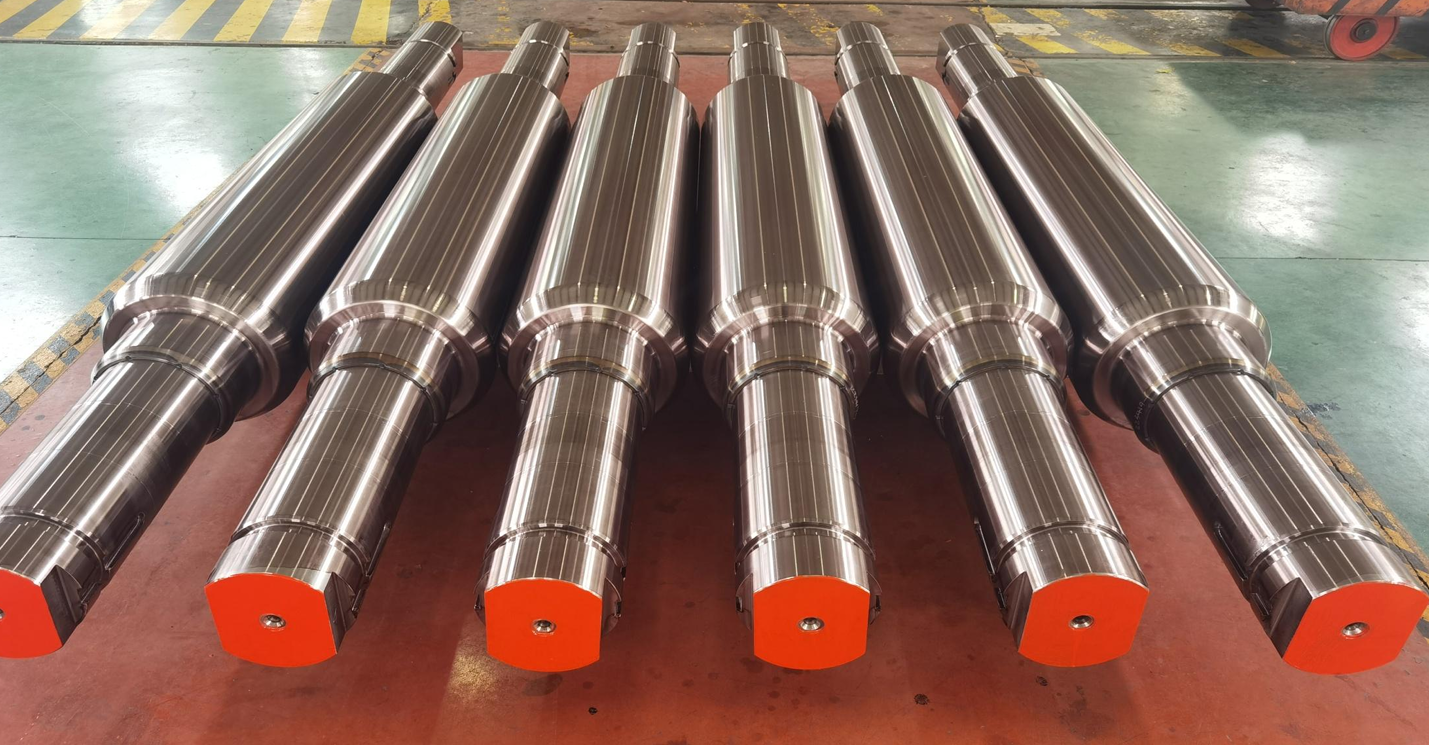

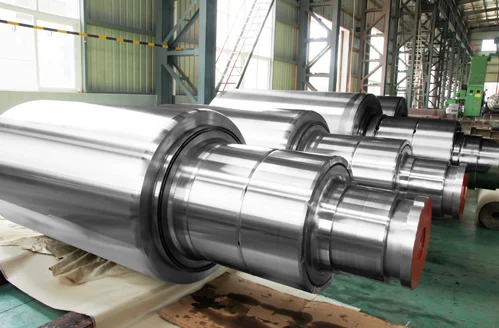

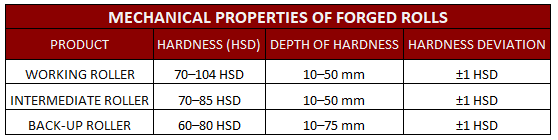

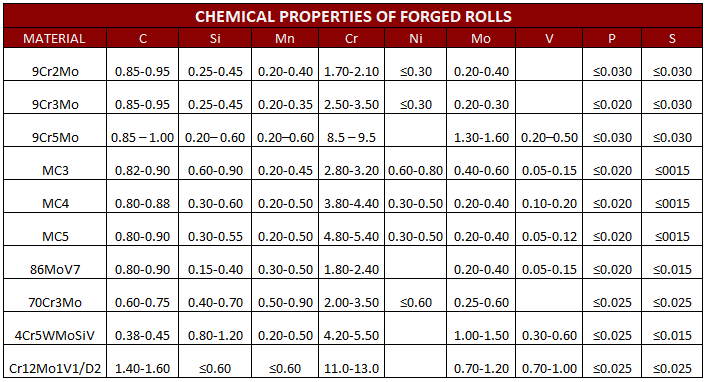

Okosu specialises in the manufacture of Cold Rolling Mill rolls used for ferrous and non-ferrous sheet rolling of copper, brass, stainless steel, aluminium, tin etc in sizes ranging from 160mm to 1600mm in dia, length upto 6 metres weighing upto 40mt/pc. Our rolls have high wear resistance, homogeneous grain structure and uniform hardness and are induction hardened for toughness. From selection of forged blanks to final dispatch, rolls undergo rigorous testing (macrostructure, microstructure, UT, MPT, Hardness, Chemical Analysis) to ensure high quality standards.

The primary rolls that come in direct contact with the metal being rolled. These are smaller in diameter compared to IMR/Back Up rolls. These are used in cold rolling and hot rolling 2Hi, 4Hi, 6Hi and 20Hi cluster mills. Material is usually 2%, 3%, 5% Cr, HSS

These are used in between work roll and Back Up roll in 6Hi CRMs and mainly use to control shape of the strips being rolled. They are made from 3%, and 5% Cr Steel.

Back Up roll is a large, heavy roll that supports the work roll in a rolling mill. It helps prevent the work roll from bending under the rolling load. These are used in 4Hi and 6Hi mills manufactured from forged steel material.

Structure

The requirement for Work Roll structure is the homogeneous distribution of the carbide. This kind of structure is subject to modification of course, in accordance with the production method; but the most sure method at examination is to take an electronic microscope picture at the roll body.

Sendzimir Mill Rolls

Okosu offers complete set of special alloy steel rolls for 20hi Sendzimir mills/cluster Mills used for high-speed rolling of non-ferrous metals like stainless steel and silicon. Due to high rolling speed and precision, such rolls are preferred by customers making very thin sheets. Our product range includes work rolls, intermediate rolls, idler rolls etc and are made from sophisticated material such as D2, D3, HSS, H11, H12 etc. Each roll is treated using advanced heat processing techniques to ensure high surface integrity, uniform hardness, and minimal deformation—even at rolling speeds.

Leveler Rolls/Flattener Rolls

We offer high-performance leveller rolls designed to straighten metal sheets and correct shape defects with precision. Using premium steels like 50CrMo4, EN31, 100Cr6, our rolls are induction-hardened for superior wear resistance and long roll life. Engineered for minimal diameter variation and excellent bending strength, okosu's leveller rolls ensure reliable performance and top-quality results in pickling, galvanizing, and cut-to-length lines.