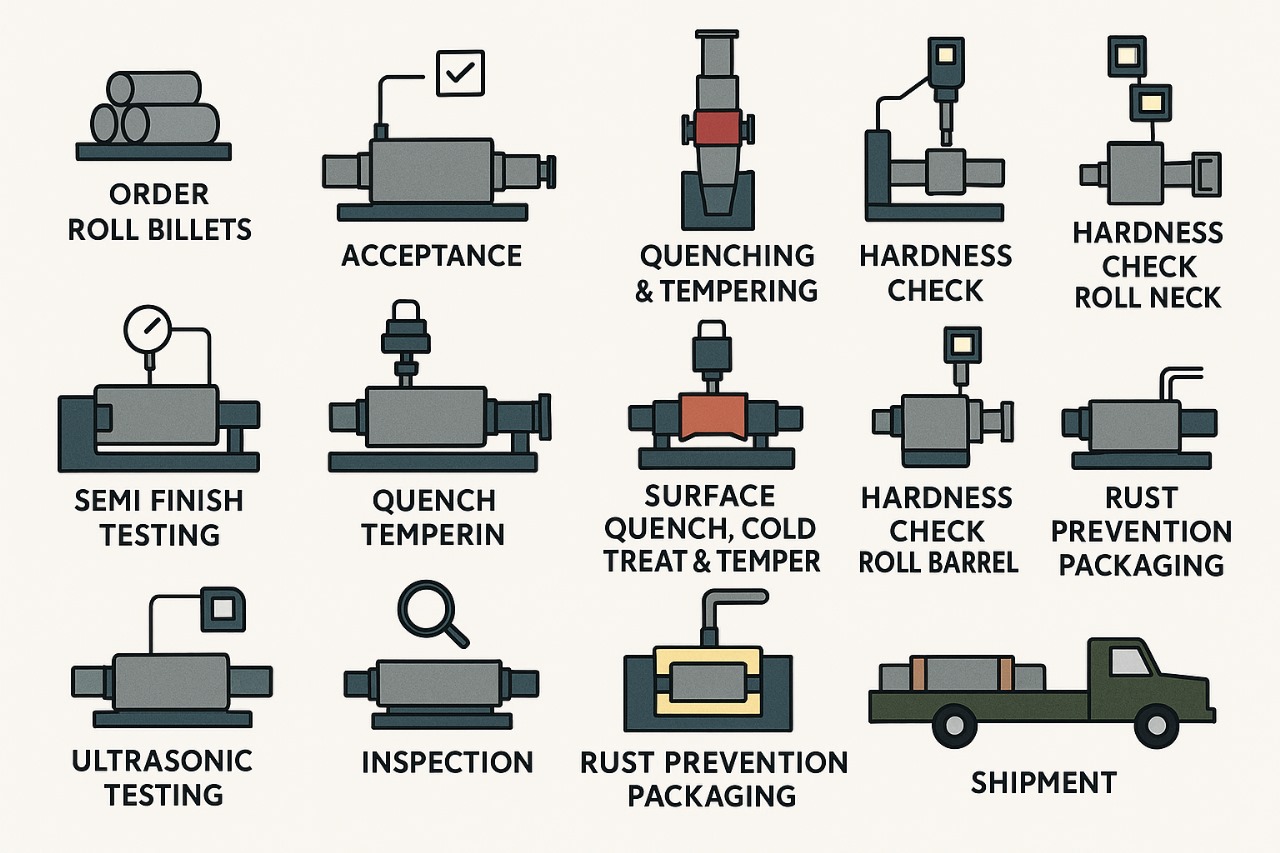

Process Flow

Step 1. Raw Material Sourcing: We start by sourcing premium forged steel blanks (2%–5% chromium) from accredited suppliers. These are refined using the LF+VAD route and ESR (Electro-Slag Remelting) processing, with a 3:1 forging ratio for purity and surface quality.

Step 2. Pre-Hardening Heat Treatment (Quenching & Tempering): The blanks undergo quenching and tempering to boost strength and wear resistance.

Step 3. Final Hardening: Next, induction hardening (single or dual-frequency) ensures uniform surface hardness.

Step 4. Cryogenic Treatment: Rolls are then cryogenically treated at -150°C to -165°C using LN₂ or CO₂ to stabilize the microstructure.

Step 5. Low-Temperature Tempering: A final low-temperature tempering relieves stress and adjusts hardness.

Step 6. Precision Machining: Precision CNC machining delivers exact dimensions and surface finish.

Step 7. Quality Assurance: Each roll is thoroughly tested for hardness, dimensions, chemistry, and structure before dispatch.

Manufacturing of Forged Roll

Infrastructure

At Okosu Forged Rolls, we ensure product quality through world-class infrastructure and advanced machinery. Our facility houses large grinding machines for precise surface finishing, CNC lathes, milling machines, medium-frequency quenching systems, and large-scale heat treatment equipment to meet demanding dimensional and performance standards. We use double-frequency induction hardening for consistent hardness and depth. Our machines can handle rolls up to 40 tonnes in weight, 1,600 mm in diameter, and 6,000 mm in length.

Quality Inspection

Quality control is the threshold of all activates at Okosu Forged Rolls. Adequate care is taken to conform to strict quality standards to ensure that the rolls are manufactured as per exact technical requirements dimensionally and physically with flawless chemical composition. The entire operation from selection of raw materials to dispatch of finished products go through a series of rigorous inspections conducted by a team of expert metallurgists for destructive (physical) and non-destructive tests- ultrasonic testing, hardness testing, MPT & chemical analysis – with calibrated instruments to ensure defect free state and spotless final product. Every customer receives personal attention from the team of service specialists with each part handcrafted and machined to precise specifications and after each phase, the parts are personally inspected by experienced professionals.

Necessary test certificate for each roll is provided.

- 1. Chemical Composition

- 2. Ultrasonic Testing

- 3. MPT Tests

- 4. Hardness Test

- 5. Dimension Test

- 6. Mechanical Property Testing

- 7. Concentricity